Preparing Your Business for PAT Testing

All the things you need to know before the big day!

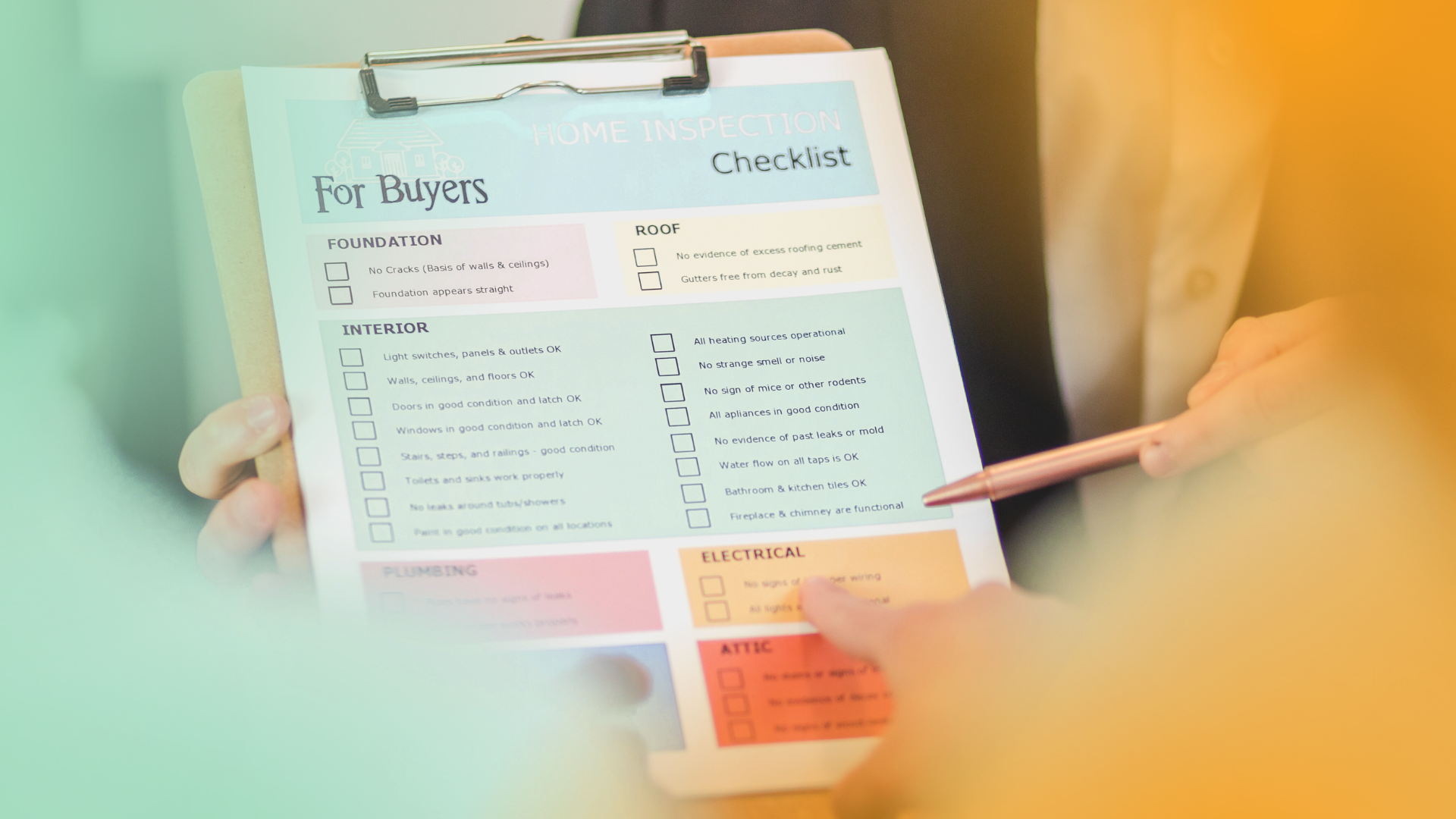

Make a List of Equipment to Be Tested

Start with anything that plugs into the mains: computers, monitors, kettles, fans, extension leads, drills, chargers, and even fridges. This helps streamline the process and ensures no items are missed. Many clients find this also acts as a valuable asset register for insurance and compliance records. Don't worry if you miss things, as we produce a list also as part of our process and visual inspection. But be warned, we won't go hunting for items inside cupboards, so have a think about hidden items that are used less.

Group Equipment by Location

Organising items by room or department makes it faster for our engineers to move through your site methodically. Labelling desks, offices or workshop zones helps save time and reduces repeat visits to the same areas. We can help you with this when doing testing for the first time.

Ensure Access to All Equipment

Please make sure we can safely reach plug sockets and appliances. Move filing cabinets, unlock rooms, and ensure keys are available for server cupboards or outbuildings. We often see delays caused by blocked or inaccessible plug points under desks and inside locked rooms.

Charge Rechargeable Equipment in Advance

Laptops, power tools, vacuum cleaners and handheld devices should be fully charged before our arrival. Should we need to unplug them to test, you're covered.

Let Staff Know in Advance

A simple notice or internal message telling your team when PAT testing will occur helps avoid surprises. Staff can shut down machines or save work before their equipment is tested. We’re flexible, but forewarning ensures smoother cooperation.

Plan for Low-Disruption Timing

We’re used to working outside of standard hours. Many clients in Horsham opt for early morning, evening or weekend visits to minimise downtime. We're happy to arrange a time that suits your schedule.

Know What to Expect on the Day

Our qualified engineer will carry out a visual inspection of each item, followed by an electrical test for earth continuity, insulation resistance and leakage. Labels will be applied to every item tested, and you’ll receive a full digital certificate on completion, often on the same day.

Why Local Businesses in Horsham Choose Us

✔ Serving West Sussex and Surrey for 15+ years

✔ City & Guilds-qualified engineers (C&G 2377)

✔ Enhanced DBS checked, fully insured

✔ Rated “Excellent” for speed, clarity and reliability

✔ Certificate and itemised reports delivered promptly

Ready to Book or Need Advice?

If you're a Horsham-based business preparing for PAT testing, we’re here to help. Get in touch for a no-obligation quote or to schedule a site visit at a time that works for you.